PowerLabs Rail Gun Research Progress!

Page description:

This page carries the images and videos of the Rail Gun construction effort; a 120-hour endeavor that cost approximately $800 of my own money, not counting sponsor-supplied materials. All images are high resolution; the original can be seen by clicking on the thumbnail.

This page is no longer being updated. For current information on project status and testing progress please go to the Rail Gun Testing Page.

Day-By-Day Project advances and current project status:

10/18/02: The gun is READY for the presentation tomorrow (120 hours of work). Today I put the stickers on and checked everything electrically. It has not been tested because I do not have a H.V. charging power supply, but I have enough faith in my design and I have tested everything aside from an energized rail test to be fairly confident that it should work. Tomorrow it will be fired for the first time ever at the Wisconsin Dells Teslathon. I had 4 people scrutinize my design today; The master machinist at the ME department, two machine shop supervisors at the shop where I work, and my project advisor. This is what I will need before I can fire the gun at the University laboratories:

10/18/02: The gun is READY for the presentation tomorrow (120 hours of work). Today I put the stickers on and checked everything electrically. It has not been tested because I do not have a H.V. charging power supply, but I have enough faith in my design and I have tested everything aside from an energized rail test to be fairly confident that it should work. Tomorrow it will be fired for the first time ever at the Wisconsin Dells Teslathon. I had 4 people scrutinize my design today; The master machinist at the ME department, two machine shop supervisors at the shop where I work, and my project advisor. This is what I will need before I can fire the gun at the University laboratories:

1- Plastic Projectile Ram Rod.

1- Plastic Projectile Ram Rod.

2- Capacitor Bank Box must be closed with INSULATED (nylon?) bolts.

3- Bleeder/charge equalizing resistors must be placed across every capacitor (I was actually looking for those. Anyone have 32 50kOhm 10W wire wound resistors?)

4- Better HV connectors must be installed.

5- Schematic for the entire gun to be drawn up (I had that done for a while now).

Nothing major really. Than after I do this and submit a complete report to my advisor I will be able to research it at the University lab. Until than its more machine work for me, and more parts to buy :-/

10/17/02: Two days to go. Added current limiting charging resistor (225W 900Ohms) and safety discharge resistors (4x 25000Ohms 75W in parallel), also made some High Voltage and Stored Energy warning stickers for the gun (University Public Safety actually requires this), added a sticker from my sponsor for the capacitor bank.

10/17/02: Two days to go. Added current limiting charging resistor (225W 900Ohms) and safety discharge resistors (4x 25000Ohms 75W in parallel), also made some High Voltage and Stored Energy warning stickers for the gun (University Public Safety actually requires this), added a sticker from my sponsor for the capacitor bank.

10/16/02: Today I got the ultra-pure aluminum bar (1100Al) for my projectiles. First I milled it down from 1/4″ thickness to 0.23″ (the rail spacing), and than I milled it from 1″ width to 0.630″. I used the foot long machined bar to re-set the spacing on the entire Rail Gun, so that the bore is now perfectly straight and VERY tight fitting for the projectiles. I than cut a couple of inch long projectiles, each one weighting approximately 6 grams (density for Al = 2.7g/cc). I fitted one into the barrel and fired it with 100PSI using the machine shop air line. To my surprise it came out fast enough to blast right through the welding booth protective screen! I tried a second shot today with 300PSI at the lab. According to the program Slava wrote me to simulate the injector’s performance the exit velocity should be just under 200m/s (700fps). I am not sure what the actual value was but it cut right through the box I had to stop it and ended up hitting a piece of wood behind the box. THIS IS AS POWERFUL AS THE INJECTOR CAN BE. According to the program the injector should be imparting 120joules of Kinetic energy into the projectile. I also finished wiring the gun and making High Voltage connectors for it: Tomorrow I hope to get speed measurements for the injector and MAYBE (unlikely) do some powered testing.

10/16/02: Today I got the ultra-pure aluminum bar (1100Al) for my projectiles. First I milled it down from 1/4″ thickness to 0.23″ (the rail spacing), and than I milled it from 1″ width to 0.630″. I used the foot long machined bar to re-set the spacing on the entire Rail Gun, so that the bore is now perfectly straight and VERY tight fitting for the projectiles. I than cut a couple of inch long projectiles, each one weighting approximately 6 grams (density for Al = 2.7g/cc). I fitted one into the barrel and fired it with 100PSI using the machine shop air line. To my surprise it came out fast enough to blast right through the welding booth protective screen! I tried a second shot today with 300PSI at the lab. According to the program Slava wrote me to simulate the injector’s performance the exit velocity should be just under 200m/s (700fps). I am not sure what the actual value was but it cut right through the box I had to stop it and ended up hitting a piece of wood behind the box. THIS IS AS POWERFUL AS THE INJECTOR CAN BE. According to the program the injector should be imparting 120joules of Kinetic energy into the projectile. I also finished wiring the gun and making High Voltage connectors for it: Tomorrow I hope to get speed measurements for the injector and MAYBE (unlikely) do some powered testing.

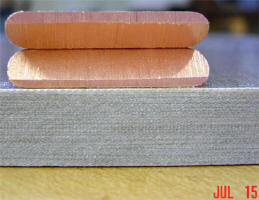

10/15/02: After only a couple of shots with air in the Rail Gun the rails were literally spitting out the PFA film insulator and Vinyl tape I was using to keep them from contacting the projectile until it had 2 and a half inches of rails behind it (this is important because without a stable magnetic field behind it to push it forward the projectile will either jump back or not accelerate at all on meeting the rails). I devised what I now thing to be the best solution for the problem; I ordered a 12×12″ 1/32″ thick Glass Fibre filled PTFE (Teflon) sheet, machined the rails down to 1/31″, cleaned everything with industrial degreaser, applied plenty of metal/plastic epoxy to the rails and glued the sheets under pressure. It is impossible to glue fluoropolymers (specially Teflon) unless they have been chemically treated. Melting them in place is also not an option. My hope was that because it is glass filled this sheet would adhered thanks to its porosity. I seem to have guessed right; the sheet seemed very rough and abrasive and bonded (as far as I can tell) nicely to the copper, but after I ran a sharpened mill bit over them they became perfectly smooth and slippery (glass filled PTFE has almost the same coefficient of friction as Teflon). This looks like a good solution.

10/15/02: After only a couple of shots with air in the Rail Gun the rails were literally spitting out the PFA film insulator and Vinyl tape I was using to keep them from contacting the projectile until it had 2 and a half inches of rails behind it (this is important because without a stable magnetic field behind it to push it forward the projectile will either jump back or not accelerate at all on meeting the rails). I devised what I now thing to be the best solution for the problem; I ordered a 12×12″ 1/32″ thick Glass Fibre filled PTFE (Teflon) sheet, machined the rails down to 1/31″, cleaned everything with industrial degreaser, applied plenty of metal/plastic epoxy to the rails and glued the sheets under pressure. It is impossible to glue fluoropolymers (specially Teflon) unless they have been chemically treated. Melting them in place is also not an option. My hope was that because it is glass filled this sheet would adhered thanks to its porosity. I seem to have guessed right; the sheet seemed very rough and abrasive and bonded (as far as I can tell) nicely to the copper, but after I ran a sharpened mill bit over them they became perfectly smooth and slippery (glass filled PTFE has almost the same coefficient of friction as Teflon). This looks like a good solution.

10/14/02: First day in months that I don’t machine something at the shop. Today I hooked up a dual trace 60MHz Oscilloscope to the Rail Gun, charged it up to 14.5V with a DC power supply and obtained waveforms for discharges with both the entire rail length (short circuited by a piece of copper at the end) and for the beginning of the rails switched by a projectile. The shortest pulse obtained was 63.4uS for the entire rail length. The projectile switched pulse was longer, owning to the fact that the low voltage used did not allow for a high current to flow through the relatively poor connection between the rails and projectile. Voltage reversal was 16%. Everything is looking up for the high power test on Wednesday! More information about the waveform analysis to be posted on the Rail Gun page. Click on the test setup to watch the projectile switched discharge test video.

10/14/02: First day in months that I don’t machine something at the shop. Today I hooked up a dual trace 60MHz Oscilloscope to the Rail Gun, charged it up to 14.5V with a DC power supply and obtained waveforms for discharges with both the entire rail length (short circuited by a piece of copper at the end) and for the beginning of the rails switched by a projectile. The shortest pulse obtained was 63.4uS for the entire rail length. The projectile switched pulse was longer, owning to the fact that the low voltage used did not allow for a high current to flow through the relatively poor connection between the rails and projectile. Voltage reversal was 16%. Everything is looking up for the high power test on Wednesday! More information about the waveform analysis to be posted on the Rail Gun page. Click on the test setup to watch the projectile switched discharge test video.

10/12/02: Today, exactly one week away from the Wisconsin Dells Teslathon where I hope to present the Rail Gun, the device is COMPLETED and READY TO BE FIRED. The entire gun was disassembled and the rails were thoroughly cleaned with degreaser and pure Isopropyl alcohol. I than milled the first inch and a half of the contact face to be 0.001″ lower than the rest of the rails and put Vinyl tape over that. I than experimented with Teflon tape as a means of insulating the other inch of the rails but that did not work (too fragile). I resorted to PFA film for the last inch; it is stronger than Teflon and has the same 500F working temperature. This is a very critical part of the gun; if the projectile scratches or melts this tape it will contact the rails too soon and acceleration will be non optimal. I am currently looking into better ways of ensuring that power is applied only after the projectile has some rail length behind it. Below you will see some pictures of the completed device. Although the gun is ready I still have some optimizations to make; namely installing bleeder resistors across each cap sub bank, installing charging/discharge resistors on the spark gap, and wiring the 24K gold plated HV connectors to the bank. Time to go out and party to celebrate this major stepping stone in my project 🙂 Monday I will test it under power and obtain current waveforms of the discharge.

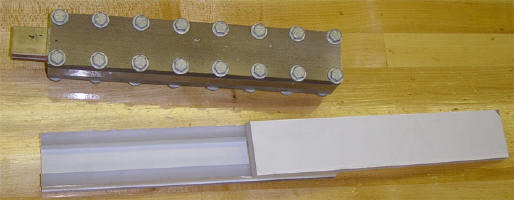

10/11/02: T-8 and counting. 8 hours of work today; Despite very close manufacturing tolerances it is normal for electrolytic capacitors to have very large variations in capacitance due to the chemical nature of their dielectric. In order to avoid unequal current distribution which can be very harmful to the capacitors at the extremely high current levels my gun will be running it is desirable to have all the capacitor values as close to each other as possible. My solution for that was to divide the 32 capacitors into 8 banks of 4 parallel capacitors each. By doing that instead of wiring them all individually I can make the current distribution more equal and also make the pulse waveform more uniform. Still, there was the problem of how to arrange them all so that each sub bank of 4 would have the same capacitance of the other 8 sub banks. My friend and fellow scientist Slava Persion from SVBx Labs came up with a very clever Genetic Algorithm program that finds the solution in less than a couple of seconds. If every combination were to be tried blindly it would take 5.5 * 10^22 years to find the solution (on a P4, 1.9GHz).. After a few seconds the program was able to arrange all 32 capacitors in such a fashion that each sub bank only varies 0.02% from the average of 6176.5uF. With the optimum configuration in hand I disassembled the entire capacitor bank, cleaned out the capacitor box and every single capacitor individually, drilled and installed the 24K gold plated high voltage connectors on the side of the box, and re-assembled the capacitor bank. I also disassembled the entire Rail Gun, but didn’t get around to working on it because I had a party to go to 🙂

10/11/02: T-8 and counting. 8 hours of work today; Despite very close manufacturing tolerances it is normal for electrolytic capacitors to have very large variations in capacitance due to the chemical nature of their dielectric. In order to avoid unequal current distribution which can be very harmful to the capacitors at the extremely high current levels my gun will be running it is desirable to have all the capacitor values as close to each other as possible. My solution for that was to divide the 32 capacitors into 8 banks of 4 parallel capacitors each. By doing that instead of wiring them all individually I can make the current distribution more equal and also make the pulse waveform more uniform. Still, there was the problem of how to arrange them all so that each sub bank of 4 would have the same capacitance of the other 8 sub banks. My friend and fellow scientist Slava Persion from SVBx Labs came up with a very clever Genetic Algorithm program that finds the solution in less than a couple of seconds. If every combination were to be tried blindly it would take 5.5 * 10^22 years to find the solution (on a P4, 1.9GHz).. After a few seconds the program was able to arrange all 32 capacitors in such a fashion that each sub bank only varies 0.02% from the average of 6176.5uF. With the optimum configuration in hand I disassembled the entire capacitor bank, cleaned out the capacitor box and every single capacitor individually, drilled and installed the 24K gold plated high voltage connectors on the side of the box, and re-assembled the capacitor bank. I also disassembled the entire Rail Gun, but didn’t get around to working on it because I had a party to go to 🙂

10/10/02: T-9 and counting. 4 hours of machine shop work today (had an exam at 6PM) and now the two power bus slots are cut on the capacitor box and all the wires are silver soldered in place at the capacitor end terminal busbars. Tomorrow I will re-arrange all the capacitors so that each sub bank of 4 caps has the same capacitance and also install the HV connectors for the gun. The project will than be done, minus the bleeder and discharge resistors that is. I am currently looking for a supplier for those.

10/10/02: T-9 and counting. 4 hours of machine shop work today (had an exam at 6PM) and now the two power bus slots are cut on the capacitor box and all the wires are silver soldered in place at the capacitor end terminal busbars. Tomorrow I will re-arrange all the capacitors so that each sub bank of 4 caps has the same capacitance and also install the HV connectors for the gun. The project will than be done, minus the bleeder and discharge resistors that is. I am currently looking for a supplier for those.

10/09/02:T-10 and counting. 5 hours today: Finished off the spark gap today and milled one gap for the rail wires. The gun/cap bank combo is heavy enough that I am starting to struggle in getting it on and off the work table and carrying it around the shop so I went off and bought 4 small wheels and bolted them under the capacitor box. Went down to the machine shop, pressure tested the injector to 310PSI, and than fired the gun (just air) at 300PSI multiple times to evaluate what the recoil does with wheels on (it rolls back almost 1cm). Here is what it sounds like at 300PSI: Maximum Power Dry Firing Video.

Tomorrow I want to solder the wires in place and thus finish the gun. Still have to buy resistors and install the connectors on it, but I will do those later on. I also have an oscilloscope on order for the lab so I should have circuit discharge waveforms shortly. Aside from machining a few projectiles my work at the machine shop for this gun is almost complete 🙂

10/08/02: T-11 and counting. 7 hours of machine shop work today; drilled, threaded and countersunk all the holes for the box top and the attachments for the gun to the capacitor box top. Also drilled/countersunk/threaded the holes for the spark gap attachment into the capacitor box. I spent ages with the master machinist at the shop making a moving electrode for the adjustable spark gap at the lathe and than the electrode broke off, so I’ll have to do that again tomorrow. I filmed a close up video of the gun being fired with air at 100PSI so that I could observe the water condensation after the barrel. It is quite interesting. I also fired a nylon washer out of the gun into a can using the shop’s 100PSI air line as a gas source. The washer was 1/8″ thick and also smaller than the rails in width so it didn’t come close to sealing the 1/4″ x .6″ barrel a huge gap in all directions inside the barrel, but it still came out fast enough that on hitting the bottom of the can it broke off in two pieces and sent the can flying backwards. Very neat video, definitely worth watching. Click on the pictures below to download the respective videos.

10/08/02: T-11 and counting. 7 hours of machine shop work today; drilled, threaded and countersunk all the holes for the box top and the attachments for the gun to the capacitor box top. Also drilled/countersunk/threaded the holes for the spark gap attachment into the capacitor box. I spent ages with the master machinist at the shop making a moving electrode for the adjustable spark gap at the lathe and than the electrode broke off, so I’ll have to do that again tomorrow. I filmed a close up video of the gun being fired with air at 100PSI so that I could observe the water condensation after the barrel. It is quite interesting. I also fired a nylon washer out of the gun into a can using the shop’s 100PSI air line as a gas source. The washer was 1/8″ thick and also smaller than the rails in width so it didn’t come close to sealing the 1/4″ x .6″ barrel a huge gap in all directions inside the barrel, but it still came out fast enough that on hitting the bottom of the can it broke off in two pieces and sent the can flying backwards. Very neat video, definitely worth watching. Click on the pictures below to download the respective videos.

10/07/02: T-12 and counting. I was at the machine shop today from 5PM to 8:30PM and finished most of the capacitor bank box. Now it has a 2″ wide triangle in each corner where the top will bolt to and a wide polycarbonate bar across the middle to give it more structural rigidity. Also cut, machined and drilled the two end terminals. Tomorrow I will drill, thread and countersink 8 bolt holes through the top and box, install the spark gap, and than try to make a mount for the gun to couple to the box top. We’ll see. After that all that I just have to solder the wires into the capacitor terminals, make connections inside the bank, install the resistors, and it will be DONE!

Minus charging supply of course :-/ I’ll have to see what to do about that… No photos today; I’ll make you wait until I pull the wrapping of the capacitor bank.

10/04/02: Glued the capacitor bank box together, something that involved 3 hours of careful manipulation of all sorts of clamps, weights and trigonometric instruments, as well as the inhalation of enough 1,2 Dichloroethane to pass out a horse. The capacitor bank was such a tight fit inside the box that if all the bolts didn’t line up perfectly it simply would not fit! Talk about close tolerances 🙂 I than went to a bodybuilding seminar by Cornelius Junior and came back to the machine shop for another 3 hours of machining, I cut, milled, glued, drilled and tapped 5 pieces of 1/2″ polycarbonate and assembled the safety variable spark gap that will protect the bank from overcharging and also provide a means of manually discharging it from outside the box without having to come into contact with the live circuit. Needless to say, this spark gap will be current limited. A non current limited discharge from this bank would explode the gap to pieces.

10/04/02: Glued the capacitor bank box together, something that involved 3 hours of careful manipulation of all sorts of clamps, weights and trigonometric instruments, as well as the inhalation of enough 1,2 Dichloroethane to pass out a horse. The capacitor bank was such a tight fit inside the box that if all the bolts didn’t line up perfectly it simply would not fit! Talk about close tolerances 🙂 I than went to a bodybuilding seminar by Cornelius Junior and came back to the machine shop for another 3 hours of machining, I cut, milled, glued, drilled and tapped 5 pieces of 1/2″ polycarbonate and assembled the safety variable spark gap that will protect the bank from overcharging and also provide a means of manually discharging it from outside the box without having to come into contact with the live circuit. Needless to say, this spark gap will be current limited. A non current limited discharge from this bank would explode the gap to pieces.

10/03/02: Drilled and bolted down the 0.064″ thick oxygen free copper bus bars that connect all 32 capacitors in the Rail Gun 20kJ 360MW power supply. Tomorrow I will cut, mill and drill the two end terminals and figure out a way of connecting them to the 16 oxygen free AWG 8 wires that go to the rails. I also hope to do some more work on the capacitor bank box. Maybe add wheels and a handle to it, considering how heavy this is turning out to be :-/

10/03/02: Drilled and bolted down the 0.064″ thick oxygen free copper bus bars that connect all 32 capacitors in the Rail Gun 20kJ 360MW power supply. Tomorrow I will cut, mill and drill the two end terminals and figure out a way of connecting them to the 16 oxygen free AWG 8 wires that go to the rails. I also hope to do some more work on the capacitor bank box. Maybe add wheels and a handle to it, considering how heavy this is turning out to be :-/

10/02/02: First test firings: Machined and drilled the rest of the capacitor busbars today. Looks like they will need some more work before I can get everything to fit. Today I wired a push button switch to the injector valve, connected the tank to a 2600PSI air tank with a regulator and attempted a few discharges; first a 200PSI dry shot (very loud, the gun sounds like a pistol) which blew some pieces of wood off the ground a couple feet ahead of the muzzle. Secondly a 100PSI shot with a very large and heavy copper projectile, and finally, a 200 PSI shot with the same projectile, which consisted in a very poorly fitting copper bar some .25x.55×3″. The projectile was very heavy and didn’t seal very well with the barrel, so these shots by no means represent what the injector is capable of, nor what the gun will ultimately be shooting.

10/01/02: The objective today was to machine new projectiles for the injector and video a test firing at high pressures. After hooking up the compressor to the injector tank I found out that as feared the compressor was destroyed during previous tests (during which it got up to 220PSI). It now stops at 80PSI due to (this was revealed during the autopsy) a damaged rubber seal which was due to excessive heat.

Today I got my advisor to look at the gun for the first time and give me the “O.K.” I needed to fire it. Everything is ready to go except for the fact that now I will be running the injector off a large air storage tank and regulator so I had to prepare a high pressure air line to quick connect with the regulator. Now that I have one I will be able to finally fire the injector, tomorrow. I am also getting a dual trace Oscilloscope soon to measure the injection velocity. 19 days until deadline. I don’t think I am going to make it. At least not everything I wanted to get done 🙁 But hey, the pessimist is never disappointed, right?…

9/30/02: Insulated the gun cables using electrical tape, squared off the gun mount sides and the injector rails at the mill, bolted the injector end plate in place, screwed the tank in (a process which involved taking the injector off the mount and gun) and did a few 100PSI test firings. The gun is now COMPLETE!!!

The finished Device:

Honestly, I think the gun looks better (cleaner, lighter) without that huge air tank next to it, but since this is about functionality more than looks, it’ll stay. I am currently investigating the possibility of running a full unregulated Nitrogen gas tank line (that’s almost 3000PSI) to the injector through a special valve for supersonic injection velocities, but for now this is what the gun will look like. Tomorrow I hope to finally test fire it at high pressures and video it.

9/28/02: Machine shop is closed today but with no time to waste I shrink wrapped the gun wires in my dorm room.

9/28/02: Bought coaxial connectors and heat shrink tubing at Radio Shack. I will use coax connectors to connect the charger to the capacitor bank, and insulate the rail gun connections with heat shrink. $14.

9/27/02: 7 hours of machine shop work today. First I shortened the two 1/2″ polycarbonate sheets that rise the gun from its mount so as to make the gun lower; this will provide less angular momentum at the base and the reduced torque will make it less likely for the gun to break off its mount due to recoil. I than cut 2 square 1/4″ thick polycarbonate sheets, glued them to the gun mount risers, glued the risers to the base, drilled 4 holes in each sheet, so now the gun bolts to the mount through them. I noticed one of the rails was slightly behind the muzzle of the gun, so I had to loosen every single bolt, realign them, and than re-tighten all the bolts. I removed the injector, drilled 4 holes in the back, an threaded them to 10 – 24. Also drilled and countersunk 4 holes on the injector back plate. Now all that is left to do is square off the sides of the mounting brackets on the mill, square off the back of the Teflon injector rails, screw the back plate on, screw the tank onto the back plate, insulate the wires coming out of the gun and hook it up to the capacitor bank (not yet completed). This weekend I will insulate the gun wires, and MONDAY it will be COMPLETE and READY TO FIRE! I will try and hydrostatically test the tank to 300PSI and celebrate by testing the injector/gun assembly with compressed air at that pressure (If the compressor collaborates). Everything is looking SOOO good, but I won’t post any pictures until the gun is ready now; this page is getting too large.

9/26/02: 5 hours of machine shop work again today; First I melted the old solder out of the damaged rail, sandblasted it clean, flushed it and re-soldered 8 new wires on. Than I milled both rails smooth again (excess solder and heat made their surfaces somewhat irregular) and fitted them on the gun. Using a router I cut all the screw heads on the injector flush, measured and cut a 1/2″ polycarbonate sheet for form a 1 foot long, 1″ high base for it. This base will attach the gun to its power supply. I still need to glue the base together and mill the plates it will use to bolt on to the gun, than I will fit the end plate onto the injector, polish the rails, insulate their first 2″ with PFA film, bolt everything together and it will be ready to go! I should have everything ready by Friday. Next week the complete Rail Gun will be test fired using compressed air at the system’s maximum capacity. A good day at last 🙂

9/26/02: 5 hours of machine shop work again today; First I melted the old solder out of the damaged rail, sandblasted it clean, flushed it and re-soldered 8 new wires on. Than I milled both rails smooth again (excess solder and heat made their surfaces somewhat irregular) and fitted them on the gun. Using a router I cut all the screw heads on the injector flush, measured and cut a 1/2″ polycarbonate sheet for form a 1 foot long, 1″ high base for it. This base will attach the gun to its power supply. I still need to glue the base together and mill the plates it will use to bolt on to the gun, than I will fit the end plate onto the injector, polish the rails, insulate their first 2″ with PFA film, bolt everything together and it will be ready to go! I should have everything ready by Friday. Next week the complete Rail Gun will be test fired using compressed air at the system’s maximum capacity. A good day at last 🙂

9/25/02: I thought yesterday was a bad day but hey, what do you know; in light of today yesterday doesn’t even look that bad any more; start off with trying to solder eight AWG 8 oxygen free high current wires on a .200″ slot in an oxygen free copper rail using an oxygen/acetylene torch; first the wires wouldn’t go in the slot, than the solder wouldn’t melt (high silver content 1100F solder), finally a lower temperature solder did melt but wouldn’t adhere. The end result? 16 feet of expensive wire wasted and a rail potentially ruined.

9/25/02: I thought yesterday was a bad day but hey, what do you know; in light of today yesterday doesn’t even look that bad any more; start off with trying to solder eight AWG 8 oxygen free high current wires on a .200″ slot in an oxygen free copper rail using an oxygen/acetylene torch; first the wires wouldn’t go in the slot, than the solder wouldn’t melt (high silver content 1100F solder), finally a lower temperature solder did melt but wouldn’t adhere. The end result? 16 feet of expensive wire wasted and a rail potentially ruined. If I can’t sandblast it clean tomorrow I will have to build a whole new rail. The second rail soldered fine though. Then comes cutting seven 1′ long, 2.5″ wide 0.064″ thick oxygen free copper buss bars for the capacitor bank using a guillotine-type sheet metal cutter; first of all it was very difficult given that the material was thicker than what the cutter was designed for. Secondly, a measurement mistake means now I only have 6 bars, and will have to order a new sheet of copper just to cut a single bar from it.

If I can’t sandblast it clean tomorrow I will have to build a whole new rail. The second rail soldered fine though. Then comes cutting seven 1′ long, 2.5″ wide 0.064″ thick oxygen free copper buss bars for the capacitor bank using a guillotine-type sheet metal cutter; first of all it was very difficult given that the material was thicker than what the cutter was designed for. Secondly, a measurement mistake means now I only have 6 bars, and will have to order a new sheet of copper just to cut a single bar from it.

Today was a useless and expensive day. Hopefully tomorrow will be better.

9/24/02: Some days it is just not my day… Tried drilling 8 holes in each rail to make the connections for the 8AWG oxygen free wires and ended up breaking 2 drill bits. The second one actually EXPLODED and sent drill shrapnel all over the machine shop. All that at a measly 1600RPM (I don’t think that’s unreasonable at all for copper, even without coolant, and the shavings I was getting didn’t seem to be discolored). Ended up spending 3 hours to remove the drill bits and mill slots on the rails as opposed to having 8 separate holes. The rails are all irregular in the ends now. I’ll solder the wires on them with high temperature silver solder and than have to mill them again. Hopefully this will all happen tomorrow… If I can make a mount for the gun too that’d make my day, but I probably won’t have the time :-/

9/23/02: Again 5 hours of machine shop work today (3:30PM – 8:30PM, no dinner). I started off by recovering the 1300cc air tank from the paint booth, re-attaching the solenoid to the valve and the reducer to the valve exit (they were removed so as not to be painted) and wiring the solenoid for AC duty. I than borrowed a variable 0 – 20V 0-30A DC power supply to run the air pump and hooked it up to the valve on the tank. The first attempt at pumping it up resulted in the rubber hose disconnecting from the pump at 220PSI and flapping all over the place. I fixed it by holding it with a brace for the next run. The second attempt resulted in the hose breaking off the pump at 80PSI. Again I braced it, but this time I was more careful to place the brace further back on the connection. For the 3rd run the pump functioned for a few minutes, reached 195PSI, and than went up in smoke! I guess I couldn’t expect *too* much from a 13 dollar pump… Either way, with 195PSI in the tank I placed a 8″ ^2 1″ thick wooden block one and a half feet away from the reducer and opened the valve to get a feel for the flow it lets through at that pressure. The results were very satisfactory! The blast of highly compressed air was powerful enough to send the block flying across the machine shop! I look forward to testing the entire assembly (injector in place on the RailGun) perhaps by the end of the week when I receive new spacers. For now this is all the work I am doing with the tank. Click here to watch an .mpg (1.2MB) video of the test at 195PSI.

9/23/02: Again 5 hours of machine shop work today (3:30PM – 8:30PM, no dinner). I started off by recovering the 1300cc air tank from the paint booth, re-attaching the solenoid to the valve and the reducer to the valve exit (they were removed so as not to be painted) and wiring the solenoid for AC duty. I than borrowed a variable 0 – 20V 0-30A DC power supply to run the air pump and hooked it up to the valve on the tank. The first attempt at pumping it up resulted in the rubber hose disconnecting from the pump at 220PSI and flapping all over the place. I fixed it by holding it with a brace for the next run. The second attempt resulted in the hose breaking off the pump at 80PSI. Again I braced it, but this time I was more careful to place the brace further back on the connection. For the 3rd run the pump functioned for a few minutes, reached 195PSI, and than went up in smoke! I guess I couldn’t expect *too* much from a 13 dollar pump… Either way, with 195PSI in the tank I placed a 8″ ^2 1″ thick wooden block one and a half feet away from the reducer and opened the valve to get a feel for the flow it lets through at that pressure. The results were very satisfactory! The blast of highly compressed air was powerful enough to send the block flying across the machine shop! I look forward to testing the entire assembly (injector in place on the RailGun) perhaps by the end of the week when I receive new spacers. For now this is all the work I am doing with the tank. Click here to watch an .mpg (1.2MB) video of the test at 195PSI.

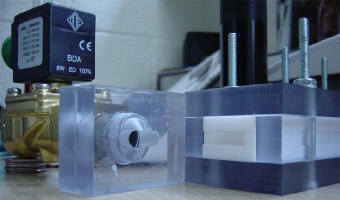

Aside from the air tank assembly today I also milled the two slots on the injector through which the 16 high current cables will attach the rails to the capacitor bank, drilled and counter sunk holes on the reducer, and drilled the holes on the injector so that it can now couple properly with the Rail Gun. These pictures show the now nearly completed Rail Gun / Injector assembly. All that is left to do now is solder the cables on the rails, trim the bolts and make a mount for the gun. I hope to get  that done by Wednesday, if time and school allows. I have made it my goal to get this project done by October 19th so I can maybe present it at the Wisconsin Dells Teslathon, and with very little time left, I am trying my very hardest at doing the fastest progress possible on the gun, while at the same time keeping everything to the very high engineering standards I have always had to all my projects. My personal goal for now is to get the entire gun COMPLETE and over with by Friday. This means having the air tank/valve/reducer/injector/rails/wires all inter connected and ready to hook up to the capacitor bank. Hopefully I can start work again on the Capacitor bank next week; it has been almost 3 months since I pulled those beauties out of the box 🙂

that done by Wednesday, if time and school allows. I have made it my goal to get this project done by October 19th so I can maybe present it at the Wisconsin Dells Teslathon, and with very little time left, I am trying my very hardest at doing the fastest progress possible on the gun, while at the same time keeping everything to the very high engineering standards I have always had to all my projects. My personal goal for now is to get the entire gun COMPLETE and over with by Friday. This means having the air tank/valve/reducer/injector/rails/wires all inter connected and ready to hook up to the capacitor bank. Hopefully I can start work again on the Capacitor bank next week; it has been almost 3 months since I pulled those beauties out of the box 🙂

9/21/02: Today I purchased 30 feet of AWG 8 Oxygen Free high current cable. I will use 8 pieces of this cable in parallel per rail to connect the gun to the capacitor bank. Ideally I should be using AWG 6 but this will do.

9/21/02: Today I purchased 30 feet of AWG 8 Oxygen Free high current cable. I will use 8 pieces of this cable in parallel per rail to connect the gun to the capacitor bank. Ideally I should be using AWG 6 but this will do.

9/20/02: Went out today and bought a 12V 250PSI pump, as well as a 1/4″ nipple for connecting the compressor to the air tank. The connector was first smeared in epoxy, than threaded into the cap, which received a second coating of epoxy, than a steel washer, another coating of epoxy, and finally a steel nut. This should ensure that the thread at the nipple is not a point where failure can occur in the tank. Once the tank was completed I cleaned it with PVC pipe cleaner and gave it a through coat of glossy black spray paint at the mechanical engineering building paint booth. You’ll have to wait until Monday to see what the finished product looks like, and hopefully than I will perform hydrostatic testing on it and if all goes well, test fire the injector.

9/20/02: Went out today and bought a 12V 250PSI pump, as well as a 1/4″ nipple for connecting the compressor to the air tank. The connector was first smeared in epoxy, than threaded into the cap, which received a second coating of epoxy, than a steel washer, another coating of epoxy, and finally a steel nut. This should ensure that the thread at the nipple is not a point where failure can occur in the tank. Once the tank was completed I cleaned it with PVC pipe cleaner and gave it a through coat of glossy black spray paint at the mechanical engineering building paint booth. You’ll have to wait until Monday to see what the finished product looks like, and hopefully than I will perform hydrostatic testing on it and if all goes well, test fire the injector.

9/19/02: Worked at the machine shop today for 5 hours and produced an air tank for my injector.

The injector is entirely made from 1 1/2″ diameter Schedule 40 PVC pipe and fittings, all treated with PVC pipe cleaner and glued together with PVC pipe glue. It should have a working pressure of 330PSI and burst well above that. The 1 1/2″ to 1/2″ adaptor that goes from the air tank to the solenoid valve was CNC machined from a 1/2″ polycarbonate plate and threaded on a lathe. The air tank dimensions are 20 x 10 x2″. It is slightly larger than I would like it to be but unfortunately any smaller and the valve would not have fitted. I in fact had to take it apart so it would screw on. Tank volume is calculated to be over 1300cc, which means that tank pressure will only drop around 4% per shot. This will provide the projectile with consistent maximum acceleration throughout its travel inside the barrel, and at the same time also allow for multiple firings with a single charge of air or nitrogen.

9/18/02: Bought all the parts for the injector air tank: 1 1/2″ dia. Schedule 40 white PVC pipe, 2 elbows, 2 end caps and a “T” junction. $15 worth. Looks like I will have to make my own 1 1/2″ to 1/2″ adaptor so I can connect the tank onto the air valve. Also bought a second 1′ square 1/2″ thick polycarbonate sheet ($22) to make the Rail Gun base from. Tomorrow I plan on assembling the entire tank and maybe getting started with the base.

9/17/02:The injector end plate and 1/2″ dia to 1/4″x 0.6″ adaptor are now complete. The assembly was made from two 1/2″ thick pieces of polycarbonate; the first one provides the valve exit pipe with a 1/2″ thread to screw onto, and the second half of the assembly consists in a 60 degree 1/2″ to 1/4″ taper with a 0.6″ wide slot running across it. Both pieces are than sandwiched together and chemically welded with 1,2-Chloroethane. The weld is good enough that the transparency of the sheets is preserved.

9/13/02: Drilled and counter sunk 12 bolt holes for the injector stack, than squared off the back of the injector so I can glue the end plate with the gas valve and 1/2″^2 to 1/4″x0.6″ adapter to it. This weekend I will look for a gas tank and hopefully by next week I will have it ready for a test fire:

9/12/02: Milled a 11/16″ deep, 1/4″ wide gap on the rail enclosure top and bottom plates and milled the injector assembly plates down to 1/4″ at the ends up to 11/16″ length so now the injector and the rail stack snap together.

9/11/02: Put another couple of hours at the machine shop to square up the sides and front of the Rail Stack and the injector assembly so that they are now both the exact same size. This will make the final fitting of things easier.

9/04/02:

Spent 3 hours at the machine shop today and milled two 1′ long, 1.176″ wide Teflon rails and two 1 1/2′ long 1/4″ square Teflon spacers for the injector.

Spent 3 hours at the machine shop today and milled two 1′ long, 1.176″ wide Teflon rails and two 1 1/2′ long 1/4″ square Teflon spacers for the injector.

9/04/02: My order from McMaster Carr finally arrived and despite a Calc quiz to study for tomorrow I went straight to the machine shop and devoted 2 hours to what will be my final projectile injector design. I have been thinking a lot about what RailGun 2.0 would look like: The “perfected” rail gun that I plan to build with all the knowledge I have gathered from this one, plus hopefully more funds (sponsorship anyone?) and more energy (if CDE likes my work with this first one and is feeling generous:). I decided that ideally the gun and the projectile injector should be the same. This would eliminate problems with alignment and also allow me to use the rails themselves as a means to accelerate the projectile further if I kept the pressure on. The idea was so good that I decided to build it right now for this gun design. Since my last 2 injector mock-ups didn’t cost any money (I built them with scrap material) I am writing them off as valuable machine shop experience and making a new injector which will couple directly into the gun and utilize nothing but the very best materials available; the projectile will ride along a virtually frictionless (K=0.01) virgin grade rectangular Teflon barrel machined to fit its dimensions with as much accuracy as I can get out of the machine. The entire enclosure will be held together by 1/2thick polycarbonate and will be designed to replicate the original rail gun in dimensions and appearance and couple to it through slots on both sheets (instead of using a continuous length of G-9 which would be unnecessarily expensive and hard to machine). Right now all the enclosure pieces have been cut out and polished. I plan on cutting the rails and spacers out some time next week, and hopefully finishing it all off within a few days. The valve I am using to deliver a burst of high pressure (up to 300PSI) nitrogen to the injector is a pilot actuated 1/2″ high flow valve. The 1/2″ coupler has an aperture area of 0.79″^2, which funnels in to the rail enclosure which is 0.14″^2 in aperture. The 5.7 to one constriction factor should in theory boost the 300PSI at the valve to 1715PSI at the injector. In practice the gain will be much lower, but still sufficient, I hope, to achieve 200m/s+ injection speeds…

8/30/02: Yet another order from McMaster Carr. This should provide me with everything I need to build my high pressure pneumatic projectile injector and also all the capacitor bus bars.

| 1 | 2 FT | 8735K262 | Teflon Rectangular Bar 1/4″ Thick, 1-1/2″ Wide, 2′ Length | $14.07 FT |

$28.14 | |

| 2 | 1 EA | 4738K157 | Brass Solenoid Valve 1/2″ NPT Female, 115 VAC | $54.19 EA |

$54.19 | |

| 3 | 1 EA | 89675K43 | Alloy 101 Oxygen-Free Copper Sheet .064″ Thick, 12″ X 24″ | $71.49 EA |

$71.49 | |

| 4 | 1 EA | 8574K32 | Polycarbonate Sheet 1/2″ Thick, 12″ X 12″, Clear | $17.05 EA |

$17.05 | |

| Merchandise Total: | $170.87 | |||||

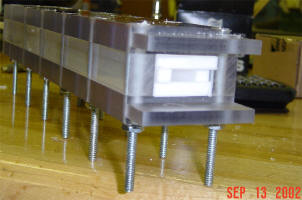

08/09/2002: At last some real progress! Today with the aid of Rob, our chief machinist, I had the rail enclosure drilled by the University’s CNC Milling machine. First the entire enclosure was put together, rails, spacers, and all, and clamped on a large vise. Than the machine was given the work piece’s dimensions and told to mill (a mill bit was used instead of a drill bit because a relatively large hole was being made along the fibers of the sides of the enclosure and it was decided that a drill might force some fibers to split, as opposed to the more gentle “scooping” action of the milling bit) eight holes starting 0.3500″ from the beginning of the piece and ending 0.3500″ from the end, running 0.2400″ from the sides. A 5/16″ hardened steel mill bit was used, which matches exactly the bolts I am using (The mill bit was destroyed in the process of milling the extremely tough material). Bolt spacing was calculated by the machine resulting in a perfect distribution of forces on the rail stack. Bolt alignment was held to 0.0001″ accuracy by the machine and the milling of the entire stack at once ensured that when everything is bolted together it will fit perfectly.

08/09/2002: At last some real progress! Today with the aid of Rob, our chief machinist, I had the rail enclosure drilled by the University’s CNC Milling machine. First the entire enclosure was put together, rails, spacers, and all, and clamped on a large vise. Than the machine was given the work piece’s dimensions and told to mill (a mill bit was used instead of a drill bit because a relatively large hole was being made along the fibers of the sides of the enclosure and it was decided that a drill might force some fibers to split, as opposed to the more gentle “scooping” action of the milling bit) eight holes starting 0.3500″ from the beginning of the piece and ending 0.3500″ from the end, running 0.2400″ from the sides. A 5/16″ hardened steel mill bit was used, which matches exactly the bolts I am using (The mill bit was destroyed in the process of milling the extremely tough material). Bolt spacing was calculated by the machine resulting in a perfect distribution of forces on the rail stack. Bolt alignment was held to 0.0001″ accuracy by the machine and the milling of the entire stack at once ensured that when everything is bolted together it will fit perfectly.

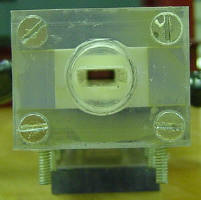

On the pictures above all parts that make up the Rail enclosure can be seen. 16 bolts are used to hold it together due to the extremely large magnetic repulsive forces that will be encountered during high power shots. The stack is WELL over designed and is, for all practical purposes, indestructible. Together, the Ultra-Coated Grade 8 5/16″-24 Hex Head Cap Screws represent 5inches of solid steel holding the rail together, and the repulsive force of the rails is spread out over 26 inches squared of G-9 fiberglass. In the unlikely even that the material should fail it would fail by de-laminating the fiberglass as opposed to flying apart.

Above the Rail Stack can be seen before drilling and after, complete and with bolts mounted. The sides of the stack were made 0.05″ too short so that when all 16 bolts are tightened the virgin grade Teflon spacers are squashed against the rails and thus provide a perfect seal. Besides eliminating arc tracking around the insulators, this will also be particularly important during plasma armature tests, where pressures inside the gun will reach tens of thousands of PSI.

View of the muzzle of the completed gun. Notice how the bolts are made almost 1/2″ longer than necessary; this will allow me to experiment with higher rail spacings, and evaluate their effect on efficiency. It would also allow me to experiment with higher capacitor bank voltages.

Specifications: Rail gap (calibre): 0.605″ wide, 0.227″ high. (15×5.8mm) The entire stack measures 2.16 x 2.36 x 12″ (5.5x6x30cm) and weights 6 pounds (2.7kg).

Now all that needs to be done is mill connections on the rails, weld mounting bolts to them, and have them re-silver plated. Than all that will be left to do will be connecting them to the capacitor bank.

08/08/2002: Today I had the G-9 Garolite composite cut into the 4 segments that will make up the rail enclosure: 2.2″ wide, 0.7″ high, and 1′ long. The CNC water jet cutter sliced through the composite which proved itself impossible to cut using a conventional band saw at a rate of 7 inches per minute and resulted in a perfect cut. Thanks Marty for letting me use the waterjet for free! Now all I need is to drill 10 holes (1 hole/inch) through the enclosure and machine contacts on the rails and the rail stack will be 100% complete!

08/08/2002: Today I had the G-9 Garolite composite cut into the 4 segments that will make up the rail enclosure: 2.2″ wide, 0.7″ high, and 1′ long. The CNC water jet cutter sliced through the composite which proved itself impossible to cut using a conventional band saw at a rate of 7 inches per minute and resulted in a perfect cut. Thanks Marty for letting me use the waterjet for free! Now all I need is to drill 10 holes (1 hole/inch) through the enclosure and machine contacts on the rails and the rail stack will be 100% complete!

I hope to have pictures of what the rail stack will ultimately look like tomorrow.

CNC Water Jet Cutting through G-9 video. The sound you hear on the background is the 50HP electric motor running the intensifier pump. (Feed rate; 7″/min, cut pressure: 50 000PSI).

08/02/2002: After a long delay in obtaining access to the University CNC water jet cutter I finally got a hold of the guy who operates the machine and convinced him to cut my G-9 rail enclosure on the machine. After telling him about my project he was so interested that he said he would do it for free (normally there is an hourly charge associated with using the machine). The machine accepts CAD (Computer Aided Design) input trough a CAD-CAM (Computer Aided Machining) converter computer to control a nozzle in 2 dimensions. The ruby nozzle expels a 55000PSI deionized water jet (produced by a double stroke 50HP intensifier pump with a shock dampener with steel walls 3″ thick!) with a 80grid garnet abrasive to cut absolutely anything with staggering precision and a smooth finish. The mach 3 hypersonic abrasive jet will slice through up to 10″ of steel in one pass without generating any heat, and with such ease that the work piece does not even have to be clamped down. After cutting through the piece the jet is stopped by a dampening water tank. Thursday I hope to have pictures and perhaps a video of my work piece being cut. Waterjet cutting was chosen because the inter woven fiber glass matrix of the material would destroy any saw blade I used, and also because the CNC cut will make tolerances much tighter, resulting in a better fitting enclosure.

08/02/2002: After a long delay in obtaining access to the University CNC water jet cutter I finally got a hold of the guy who operates the machine and convinced him to cut my G-9 rail enclosure on the machine. After telling him about my project he was so interested that he said he would do it for free (normally there is an hourly charge associated with using the machine). The machine accepts CAD (Computer Aided Design) input trough a CAD-CAM (Computer Aided Machining) converter computer to control a nozzle in 2 dimensions. The ruby nozzle expels a 55000PSI deionized water jet (produced by a double stroke 50HP intensifier pump with a shock dampener with steel walls 3″ thick!) with a 80grid garnet abrasive to cut absolutely anything with staggering precision and a smooth finish. The mach 3 hypersonic abrasive jet will slice through up to 10″ of steel in one pass without generating any heat, and with such ease that the work piece does not even have to be clamped down. After cutting through the piece the jet is stopped by a dampening water tank. Thursday I hope to have pictures and perhaps a video of my work piece being cut. Waterjet cutting was chosen because the inter woven fiber glass matrix of the material would destroy any saw blade I used, and also because the CNC cut will make tolerances much tighter, resulting in a better fitting enclosure.

07/18/2002: After cutting them on the band saw with a guide the rail spacers had some saw marks on them, and since they will ultimately be in contact with a metal slug moving at several hundred m/s I decided that having the smoothest surface possible would be advantageous since it would allow for the lowest possible friction and thus maximum projectile velocity/minimum parts wear. I milled a 1/4″ wide groove on an aluminum plate, bolted it down, and ran an 8-segment milling bit at 3600rpm over the virgin grade Teflon rail spacers at the lowest servo setting on the mill, thus making their surfaces not only perfectly flat and parallel, but also unbelievably smooth. Spacers are 0.25″ thick and .25″ wide, making the final dimensions of the gun bore 0.2×0.63″, or 5x16mm. That’s a Today I got a very interesting comment from a Mercedes Benz engineer who was visiting campus: He happened to walk into the machine shop right as I was measuring the rails and he asked me if I was making some kind of busbar… When I explained my project to him and showed some of the materials I had on the table for it he said: “WOW, your sponsors don’t spare any money, do they?”. I thought it was pretty neat. Just wait until you see the rail stack, which is hopefully being cut by a CNC waterjet machine tomorrow. 🙂

07/18/2002: After cutting them on the band saw with a guide the rail spacers had some saw marks on them, and since they will ultimately be in contact with a metal slug moving at several hundred m/s I decided that having the smoothest surface possible would be advantageous since it would allow for the lowest possible friction and thus maximum projectile velocity/minimum parts wear. I milled a 1/4″ wide groove on an aluminum plate, bolted it down, and ran an 8-segment milling bit at 3600rpm over the virgin grade Teflon rail spacers at the lowest servo setting on the mill, thus making their surfaces not only perfectly flat and parallel, but also unbelievably smooth. Spacers are 0.25″ thick and .25″ wide, making the final dimensions of the gun bore 0.2×0.63″, or 5x16mm. That’s a Today I got a very interesting comment from a Mercedes Benz engineer who was visiting campus: He happened to walk into the machine shop right as I was measuring the rails and he asked me if I was making some kind of busbar… When I explained my project to him and showed some of the materials I had on the table for it he said: “WOW, your sponsors don’t spare any money, do they?”. I thought it was pretty neat. Just wait until you see the rail stack, which is hopefully being cut by a CNC waterjet machine tomorrow. 🙂

07/17/2002: Removed the round edges from the silver plated copper bars. When I ordered rectangular silver plated copper bars from Mc Master Carr I didn’t expect them to come with round edges and that would make it very difficult to hold them in place, so I put them on the servo assisted milling machine and took off enough material that they now have perfectly flat, smooth, parallel edges. Rail width is now 1,176″.

07/17/2002: Removed the round edges from the silver plated copper bars. When I ordered rectangular silver plated copper bars from Mc Master Carr I didn’t expect them to come with round edges and that would make it very difficult to hold them in place, so I put them on the servo assisted milling machine and took off enough material that they now have perfectly flat, smooth, parallel edges. Rail width is now 1,176″.

07/15/2002: After some time off from work during which I was looking for a suitable safety gap to protect and remotely drain the capacitor bank I decided to change the focus of my work away from the power supply and work on the rails a bit. Today I cut (on the bandsaw) the 3 foot long silver plated 1/4thick copper rail into two individual rails, each one 13.5″ long. I also made a 45 degree taper (on the belt sander) on their ends which will serve as an arc breaker should any arcing occur at the muzzle. I also cut (band saw) the virgin grade Teflon rail spacers to 1′ length each and tapered them to 45″ (belt sander), and cut all the parts (table saw) for the slug pneumatic injector. No pictures of the injector yet, but it will have a barrel length of 25cm, which means that the gun + injector assembly just fits on top of the capacitor bank. Now looking for a fast solenoid valve to control the 250PSI burst of compressed gas that will accelerate the slug for rail injection at hopefully 100m/s+.

07/15/2002: After some time off from work during which I was looking for a suitable safety gap to protect and remotely drain the capacitor bank I decided to change the focus of my work away from the power supply and work on the rails a bit. Today I cut (on the bandsaw) the 3 foot long silver plated 1/4thick copper rail into two individual rails, each one 13.5″ long. I also made a 45 degree taper (on the belt sander) on their ends which will serve as an arc breaker should any arcing occur at the muzzle. I also cut (band saw) the virgin grade Teflon rail spacers to 1′ length each and tapered them to 45″ (belt sander), and cut all the parts (table saw) for the slug pneumatic injector. No pictures of the injector yet, but it will have a barrel length of 25cm, which means that the gun + injector assembly just fits on top of the capacitor bank. Now looking for a fast solenoid valve to control the 250PSI burst of compressed gas that will accelerate the slug for rail injection at hopefully 100m/s+.

07/02/2002: Today I cut all the Polycarbonate (Lexan�) sheets for my capacitor box: The final dimensions are 24.7×12.6×8″ (63x32x20cm). Cutting the sheets was surprisingly easy with the table saw and since I used an alignment tool everything fits together perfectly. I still have to make the safety bleeder switch which I am probably going to make in the form of a variable Spark Gap, and I have to find out what size holes the high voltage coaxial cables will need, and what the rail connectors will look like before I can glue everything and remove the white plastic covering that protects the sheets from scratching during machining…

07/01/2002: It has been too hot the last couple of days (heat indexes above 100F) for any kind of work on the machine shop. Today I went down there and took advantage of the fact that there was no one in any of the workshops to snap a few pictures of the metals workshop. Both metal workshops and the non metals workshop are part of Michigan Tech’s “product realization center”. The center is designed to allow senior students to produce prototypes of their industry-sponsored design projects, and also for the graduate students in their research projects. As someone who has just completed their first year in University, I am probably the youngest person working there…

So far I still need to get clearance to use the Lathes, the CNC mill (that takes a long time, given the complexity of the machine), and the welding machines (MIG and Oxy-Acetylene). If I decide to machine the G-9 rail holder I will probably do it here since it will require carbide cutters and drills.

06/26/2002: Went down to the non-metals workshop and took some pictures of the tools there for the webpage. Arranged with the workshop supervisor for him to teach me how to utilize a digital readout, 0,0001mm accuracy milling machine this Friday. I plan on taking the 1/4″ thick, 48×48″ polycarbonate sheet down there tomorrow or Friday at the latest and cutting all the pieces for the capacitor bank enclosure. I can’t glue it just yet though since I need high voltage cable connectors and a high voltage switch and bleeding resistor to fit inside it, and I also have to decide on what the output cables will look like. I plan on using the milling machine to remove the round edges on the copper bar and making grooves for the rails on the rail assembly.

06/25/2002: Got checked out by the machine shop supervisor to utilize the non-metals workshop belt/disk sander, spindle sander, angle grinder, drill press, table saw, band saw, jigsaw, hand saw, angle saw. Also got some instructions on how to weld polycarbonate sheets together using 1,2-Chloroethane.

06/25/2002: Got checked out by the machine shop supervisor to utilize the non-metals workshop belt/disk sander, spindle sander, angle grinder, drill press, table saw, band saw, jigsaw, hand saw, angle saw. Also got some instructions on how to weld polycarbonate sheets together using 1,2-Chloroethane.

Here you can see some pictures of the Randolph non-metals center, located on the 6th floor of the Mechanical Engineering/Engineering Mechanics building of Michigan Tech.

A good deal of the Rail Gun construction will take place on this workshop; here I can cut/sand/drill/thread all the parts for the capacitor bank assembly, power supply box, and part of the structural pieces that will hold the Rail Gun to its capacitor bank. Aside from the rail enclosure which will be under extreme stress I plan on making all structural parts from Polycarbonate. I may use something cheaper on the charging supply since that is not under any sort of mechanical stress.

A good deal of the Rail Gun construction will take place on this workshop; here I can cut/sand/drill/thread all the parts for the capacitor bank assembly, power supply box, and part of the structural pieces that will hold the Rail Gun to its capacitor bank. Aside from the rail enclosure which will be under extreme stress I plan on making all structural parts from Polycarbonate. I may use something cheaper on the charging supply since that is not under any sort of mechanical stress.

06/23/2002: I got checked out by the machine shop supervisor to utilize the metal workshop sander, grinders, drill press, and band saw.

06/20/2002: Materials moved into Advanced Propulsion Laboratory:

My advisor, Dr. Brad King, made available for me this table on the laboratory, along with storage space for the material I obtained so far. The table sits next to a massive high vacuum chamber where Ion propulsion engines and other forms of advanced space propulsion are tested.

Some of the power supplies available in the laboratory include low and high voltage DC and AC stabilized and current/voltage monitored power rack supplies used to feed the Ion Engines and the vacuum chamber line degassing heaters. I will most probably be building my own capacitor charging supply for the gun however, since I want it to be portable and self contained.

The vacuum chamber by far occupies the most space in the laboratory. It is connected to a very large 2-stage water cooled oil sealed rotary pump which than connects to a very large Liquid Helium cryopump. The entire system is designed to run for days at a time testing ionic and plasma propulsion engines. Although I won’t be using it for my project (though I haven’t completely ruled out the possibility of hiding inside it when the gun is fired for the first time:) ) it will probably be featured in most of my lab pictures since it pretty much takes up the whole room. I would love to test some of my own plasma propulsion ideas on that chamber some later time, but for now my complete focus is on the RailGun project.

6/13/2002: First parts order, from Mc Master Carr:

| 1 | 1 EA | 88865K312 | Alloy 110 Silver-Plated Copper Rectangle 1/4″ Thick, 1-3/8″ Width, 3′ Length | $19.10 EA |

$19.10 | today | |

| 2 | 1 EA | 8574K85 | Polycarbonate Sheet 1/4″ Thick, 48″ X 48″, Clear | $90.35 EA |

$90.35 | today | |

| 3 | 1 FT | 84955K12 | PFA Film .001″ Thick X 24″ Wide | $3.93 FT |

$3.93 | today | |

| 4 | 4 FT | 8735K25 | Teflon Rectangular Bar 1/4″ Thick, 1″ Wide | $9.41 FT |

$37.64 | today | |

| 5 | 1 EA | 8661K127 | Grade G-9 Garolite Sheet 1/2″ Thick, 12″ X 12″, Gray-Brown | $54.81 EA |

$54.81 | today | |

| 6 | 1 PK | 91286A196 | Ultra-Coated Grade 8 Hex Head Cap Screw 5/16″-24 Thread, 2-1/2″ Lg | $5.96 PK |

$5.96 | today | |

| 7 | 25 EA | 93915A140 | High-Pressure Self-Sealing Locknut 5/16″-24 Screw Sz, Fine Thread, 9/16″ WD, 17/64″ HT | $3.40 EA |

$85.00 | today | |

| 8 | 1 PK | 98180A120 | Ultra Coated High Strength Steel Washer 5/16″ Screw Size, 11/32″ ID, 11/16″ OD,.051″ Min Thick | $2.60 PK |

$2.60 | today | |

| 9 | 10 EA | 91740A104 | Thread Restoring Bolt 1/4″-20 Coarse Thread X 1-1/4″ Long | $3.47 EA |

$34.70 | today | |

| Merchandise Total: | $334.09 | ||||||

I ended up paying $394 with the shipping. These will allow me to make the capacitor box (48×48″ polycarbonate sheet) and the rail enclosure (G-9 Garolite, Teflon spacer, PFA insulator, bolts, nuts, washers, etc), The rails will be made from the copper rectangle. I still need parts for the power supply; V and A meters, bleeder resistors, discharge switches, high voltage cables, inverter, etc… Anyone have any of this stuff?

Please Donate to PowerLabs so I can continue to fund more experiments!

© 2022 Copyright by Sam Barros. All rights reserved.

Removing any material from this site for display without consent from its author consists in an infringement of international copyright laws and can result in fines up to $50000 plus legal costs per infringement.