PowerLabs CO2 LASER!

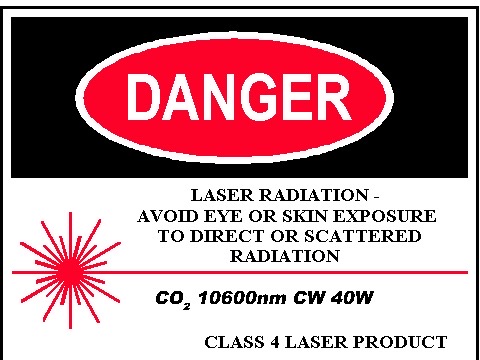

Warning:

WARNING: Do you like your eyesight? Are you familiar with all the proper safety precautions involved in dealing with a high power Laser? Do you have enough experience with High Voltage power supplies to build your own and not electrocute yourself? If not, then don’t even THINK about starting a project like this. Class 4 LASERS are the most powerful and dangerous class of lasers, and will burn flesh and retinas faster than you can realize it. Even diffuse reflections can be very dangerous.

WARNING: Do you like your eyesight? Are you familiar with all the proper safety precautions involved in dealing with a high power Laser? Do you have enough experience with High Voltage power supplies to build your own and not electrocute yourself? If not, then don’t even THINK about starting a project like this. Class 4 LASERS are the most powerful and dangerous class of lasers, and will burn flesh and retinas faster than you can realize it. Even diffuse reflections can be very dangerous.

This page is not meant as a how-to, but merely a documentary of how I went about constructing my own laser. Enjoy, but don’t try this at home…

Project Description and Goals:

Every self respecting mad scientist needs a LASER. Personally, I have been fascinated by them for longer than I can remember; The idea of a light beam that can cut and burn things from a distance has to inspire both fear and admiration in anyone.

Unfortunately for the general public, cutting lasers are, for the most part, Hollywood fiction. I have been fortunate enough to witness some pretty spectacular lasers in action, including green beam blinding flashlights (which, I believe, are in current use now), some industrial and research pulsed lasers, and, my favorite, the US Air force Airborne Chemical laser (which was supposed to be able to shoot down missiles from miles away, but in the demo I saw at Sandia National Laboratories merely bore a 4″ hole through 1/4″ acrylic), but when it comes to acquiring lasers, the most exciting thing I’ve been able to get my hands on was a green Laser Pointer, and even then I thought that it was too expensive and not worth buying.

Until now… Thanks to a generous sponsorship from Plans and Kits Unlimited, PowerLabs now has a sealed 40Watt CO2 Laser tube at its disposal. CO2 lasers are amongst the most powerful lasers in use today, and find applications in cutting, engraving, drilling and various medical uses. A 40 watt beam should be powerful enough to start a fire many tens of meters away, for example.

Theory (a simplified overview):

CO2 lasers work by exciting low pressure Carbon Dioxide gas between two mirrors, one of which is partially reflective and allows the beam to escape. Although their efficiency is amongst the highest of any gas discharge laser (circa 10%), a very large amount of heat is produced which must be dissipated. This is specially important because power output also drops as the tube heats up. Most CO2 lasers have a cooling jacket around the discharge tube, and the higher power ones also run a continuous gas flow through the discharge path to carry heat away from the tube and lenses. The light output is 10600nm, which is in the far end of the IR (Infra Red) spectrum, making the beam completely invisible aside from nigh vision equipment. IR beams are heat beams; most materials appear opaque to them and will absorb energy and heat up; if the energy absorbed is greater than the material can dissipate, the material will melt and burn. Focusing these lasers greatly improves the energy and power density, and allows them to do useful things such as cut and drill various materials. More on focusing later.

CO2 lasers work by exciting low pressure Carbon Dioxide gas between two mirrors, one of which is partially reflective and allows the beam to escape. Although their efficiency is amongst the highest of any gas discharge laser (circa 10%), a very large amount of heat is produced which must be dissipated. This is specially important because power output also drops as the tube heats up. Most CO2 lasers have a cooling jacket around the discharge tube, and the higher power ones also run a continuous gas flow through the discharge path to carry heat away from the tube and lenses. The light output is 10600nm, which is in the far end of the IR (Infra Red) spectrum, making the beam completely invisible aside from nigh vision equipment. IR beams are heat beams; most materials appear opaque to them and will absorb energy and heat up; if the energy absorbed is greater than the material can dissipate, the material will melt and burn. Focusing these lasers greatly improves the energy and power density, and allows them to do useful things such as cut and drill various materials. More on focusing later.

(E-mail me if you feel like this this theory should be expanded upon)

Power Supply and cooling:

Power Supply and cooling:

The

initial objective was to get it to work quickly. So a very simple setup was devised: Cooling is provided by an automotive windshield washer pump flowing distilled water in and out of a 1 gallon jug. The jug appears to have enough thermal mass to prevent overheating of the system during several minute runs. The pump, however, failed when running at 12 volts for an extended period of time. It seems to run stable at 9 – 10 volts for a couple minutes at a time.

initial objective was to get it to work quickly. So a very simple setup was devised: Cooling is provided by an automotive windshield washer pump flowing distilled water in and out of a 1 gallon jug. The jug appears to have enough thermal mass to prevent overheating of the system during several minute runs. The pump, however, failed when running at 12 volts for an extended period of time. It seems to run stable at 9 – 10 volts for a couple minutes at a time.

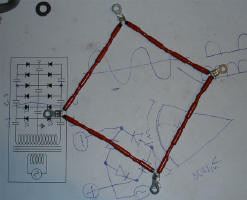

The power supply pictured above currently consists of a 15kV 20mA solid state neon sign transformer fed through a full wave voltage doubler. The transformer failed after 4 minutes run time, but it did work for the initial tests.

The current power supply consists of a 12kV 60mA 60Hz Neon Sign transformer fed through a full wave bridge rectifier. This feeds 720watts into the tube, which is excessive and will shorten tube life, but does provide for some very impressive performance.

Design overview:

Click the pictures to the left to see a nice overview of the design. No details yet since this is about to change very soon.

Click the pictures to the left to see a nice overview of the design. No details yet since this is about to change very soon.

Results!

The laser makes a narrow 1mm beam that spreads out to about 1cm in 3 meters. It is very intense from up close, instantly igniting flammable objects, and still has more than enough power to burn at 3 meters, but the drop in power level is obvious. I am looking forward to obtaining a focusing lens for this (Paypal Donations anyone?). When properly focused, the beam will be able to cut through thin metals.

The laser makes a narrow 1mm beam that spreads out to about 1cm in 3 meters. It is very intense from up close, instantly igniting flammable objects, and still has more than enough power to burn at 3 meters, but the drop in power level is obvious. I am looking forward to obtaining a focusing lens for this (Paypal Donations anyone?). When properly focused, the beam will be able to cut through thin metals.

Videos:

Woodburn: Laser burning a wooden ruler from 20cm or so away. You can see a flame following the beam as I move the ruler. What is happening here is that the laser superheats a localized spot on the ruler, causing it ignite gases that are liberated when the wood is heated. As the laser beam moves along the surface of the ruler, the flame follows its path instead of continuing to burn where it was before; the combustion is completely supported by the heat of the laser.

3MB. The background noise is the cooling pump.

Burning a piece of coal from up close; the coal absorbs laser energy very well; so much, in fact, that it throws sparks and emits a flame.

3MB. The background noise is the cooling pump.

Igniting some guncotton (nitrocellulose) from a distance. What is special about this video is that the ignition is so instant (less than 1 second), that I left the cooling off, so you can actually hear the laser. It hums faintly.

1MB

Paperburn: Laser igniting paper from 30cm or so away. You can hear a “pop” every time the paper catches.

Paperburn: Laser igniting paper from 30cm or so away. You can hear a “pop” every time the paper catches.

3MB. The background noise is the cooling pump.

Matchbox: Laser igniting a box of matches from a little over 3 meters away. It takes a little while because the laser has to burn through some paper before it gets to the matches.

Matchbox: Laser igniting a box of matches from a little over 3 meters away. It takes a little while because the laser has to burn through some paper before it gets to the matches.

3MB. The background noise is the cooling pump.

Attempting to write “POWERLABS” on a piece of cardboard. This was actually a lot harder than I expected. You can see how quickly the laser burns though.

Attempting to write “POWERLABS” on a piece of cardboard. This was actually a lot harder than I expected. You can see how quickly the laser burns though.

3MB. The background noise is the cooling pump.

Focusing and Laser Optics:

The beam is reflected by many metals, but not very efficiently. This is what makes it possible to use CO2 lasers to cut metals, although even then very high powers are required and often the metal will be treated with a black paint coating to improve power absorption. Proper IR laser mirrors are vacuum deposited Gold. Similarly, IR laser optics are made of exotic materials, such as Zinc Selenide (ZnSe). ZnSe is an amber colored crystal significantly denser than glass. It makes up the optical windows on lasers, IR cameras, and other devices operating in the low infra red range. It absorbs very little of the light that passes through it, and can be formed into lenses, such as the one pictured here. By focusing the light down into a very small spot, it becomes possible to achieve incredible power densities; some times into the millions of watts per square meter; with that much power, the surface of most materials can not dissipate heat quickly enough and the spot erupts into a small ball of plasma. Temperatures can go into the tens of thousands of degrees C, making the light emitted VERY bright!

The beam is reflected by many metals, but not very efficiently. This is what makes it possible to use CO2 lasers to cut metals, although even then very high powers are required and often the metal will be treated with a black paint coating to improve power absorption. Proper IR laser mirrors are vacuum deposited Gold. Similarly, IR laser optics are made of exotic materials, such as Zinc Selenide (ZnSe). ZnSe is an amber colored crystal significantly denser than glass. It makes up the optical windows on lasers, IR cameras, and other devices operating in the low infra red range. It absorbs very little of the light that passes through it, and can be formed into lenses, such as the one pictured here. By focusing the light down into a very small spot, it becomes possible to achieve incredible power densities; some times into the millions of watts per square meter; with that much power, the surface of most materials can not dissipate heat quickly enough and the spot erupts into a small ball of plasma. Temperatures can go into the tens of thousands of degrees C, making the light emitted VERY bright!

Much more to come 🙂 A special thanks to Robert Brown for supplying the optics!

Please Donate to PowerLabs so I can continue to fund more experiments!

© 2022 Copyright by Sam Barros. All rights reserved.

Removing any material from this site for display without consent from its author consists in an infringement of international copyright laws and can result in fines up to $50000 plus legal costs per infringement.