PowerLabs Thompson’s Coil and Disk Shooter Research:

Disk Shooter!

Disclaimer: The experiments described below are incredibly dangerous and should not be attempted by anyone who is not thoroughly familiar with the many safety procedures involved when working with lethal high voltages and high energy electrical impulses. The capacitor bank below charged to its full potential (3kilojoules) stores 15 times as much energy as a maximum power cardiac defibrillator discharge, and is CERTAIN not only to kill, but also to blow bits off from anyone who is to come into contact with it. Remember, energies above 16Joules can be lethal. Your first mistake will be your last mistake.

Now, on with the show. First, my main capacitor bank:

As seen above, it consists in 10 Nippon-Chemi Com (brown) and 10 Powerlytic (blue) capacitors inside a clear Plexiglas box measuring 70x15x15 cm and weighting a total of 13.5kilos (24pounds). All capacitors are rated for 450V max and store a 1500uF charge. This amounts to 150Joules each, or, 3000Joules in total. The capacitors are interconnected using 2cm wide, 1mm thick copper buss bars (for low inductance) and, for this particular experiment, are connected as a 900V bank at 7500uF (by changing the series/parallel arrangement it is possible to have it anywhere between 450V 30000Uf to 9000V 75uF). Above the capacitors is a Digital Multimeter reading the actual charge voltage (in this case 0volts). The multimeter is essential as it allows me to monitor the charging rate, the actual charge voltage, and any residual charge left in the capacitors after a discharge. It is also very important for safety, as one must always keep distance from a charged capacitor bank. The box serves to insulate the capacitors from one another when they are all in series (9kV) and from their environment (bits of metal, tools, and body parts must be kept away from them at all costs). It also prevents electrolyte from spilling out in the event of a capacitor failure.

Also note the 16mm^2 multi stranded copper welding cables used to connect the capacitor bank to the load. These are the thickest wires I could fit through my discharge switch connection terminal. When the capacitor discharges, the magnetic field produced around these wires is so great that they have to be kept at as far a distance as possible (which is why you see them bowed outwards here), otherwise they would repel each other with enough force to rip the connection points (this happened once and one wire was flung across the room into a wall, after snapping the bolt holding it in place).

The smaller white box next to the HV Power Supply is a variable low voltage DC power supply and is used to actuate the solenoid on the vacuum relay (discharge switch).

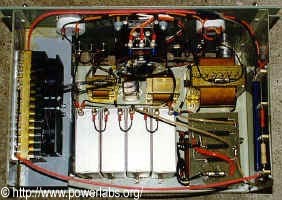

Below you can see the capacitor bank in an experiment. The large gray box on the right of the picture is a variable LASER high-voltage supply (I re-wired it internally to 7500V at 160mA max. The meters read KV and MA and the black knob is connected to a variac that allows the voltage to be changed. It also has a filament power supply (24V at a couple amperes) and a striker pulse provided by an inductor (estimated 20kV)). You can see a picture of its insides to the right.

Below you can see the capacitor bank in an experiment. The large gray box on the right of the picture is a variable LASER high-voltage supply (I re-wired it internally to 7500V at 160mA max. The meters read KV and MA and the black knob is connected to a variac that allows the voltage to be changed. It also has a filament power supply (24V at a couple amperes) and a striker pulse provided by an inductor (estimated 20kV)). You can see a picture of its insides to the right.

To the extreme left you can see a pair of blue earmuffs. Those are rated at 36DB attenuation (for gun shooting) and are an absolute MUST when conducting any type of pulsed capacitor discharge. If anything is to go wrong, a short circuit can create local sound pressure levels well above 180DB (this will be discussed later). Between the Laser Power supply and the capacitor bank two things can be seen: One is a white box: A regulated variable DC power supply, rated for 0 – 30V at 0-10A. It actuates the Jennings Vacuum relay (The tall thing standing next to the laser power supply and connected to the capacitor bank and coil. That relay is rated at 25kV 100A (2.5MEGAWATTS RMS power!).

To the extreme left you can see a pair of blue earmuffs. Those are rated at 36DB attenuation (for gun shooting) and are an absolute MUST when conducting any type of pulsed capacitor discharge. If anything is to go wrong, a short circuit can create local sound pressure levels well above 180DB (this will be discussed later). Between the Laser Power supply and the capacitor bank two things can be seen: One is a white box: A regulated variable DC power supply, rated for 0 – 30V at 0-10A. It actuates the Jennings Vacuum relay (The tall thing standing next to the laser power supply and connected to the capacitor bank and coil. That relay is rated at 25kV 100A (2.5MEGAWATTS RMS power!).

The experiment being conducted can be seen connected to the welding cables. It consists of a flat 16-turn coil (using 7mm diameter multi stranded wire) with a 15cm diameter, 3mm thick, 70 grams aluminium disk sitting right above it.

The capacitor bank is charged to a full 900V potential, and then the relay latch is released (everything is done remotely behind a Plexiglas shield located 10 meters from where the experiment is conducted) so that all the energy stored in the capacitors flows through the coil for a few microseconds. Because of the extremely short discharge times, currents of several tens of thousands of amperes are obtained, causing the coil to produce and enormously powerful increasing magnetic field, which, on passing through the disk, induces a current on it. Due to the turns ratio (16 turns coil – 1turn disk), the current through the disk is several times greater than that through the coil. This current loops around the disk and is called an Eddy current. Like any other current flow, this produces a magnetic field of opposite polarity to that of the coil, hence, the two repel. As the coil is fixed to the table, it pushes down on it (sometimes hard enough to make it bounce back up and knock things over!), and the disk is propelled upwards. By varying the charging voltage different firing speeds can be obtained.

The purpose of this experiment was to determine what type of coil works best for this application (this was done by varying number of turns, wire diameter and geometry) and how attained height varies with energy (one would expect it to vary linearly, but somehow the induction process seems to become more efficient as power levels are increased, and on certain cases the disk would go 4.3 times higher by merely doubling the energy of the pulse). A 3 kilojoule electrical impulse has the potential to lift several hundred kilograms, so in theory a track with several coils that were pulsed in a sequence could lift and carry along a load, such as a train: MagLev technology without superconductors!

Here you can see what happens at full power: With 3kJ propelling it, the aluminum disk was severely warped which caused it to spin as it came up. Striking the roof at an angle, it penetrated an inch deep into the wood (look to the left of the light bulb)! I calculated the disk’s velocity to be in the 500km/h range as it left the coil. Attempts to replicate this outdoors resulted in the disk being warped so severely that it completely lost its aerodynamic and spun out of control, stopping after climbing a good 100 meters.

Here you can see what happens at full power: With 3kJ propelling it, the aluminum disk was severely warped which caused it to spin as it came up. Striking the roof at an angle, it penetrated an inch deep into the wood (look to the left of the light bulb)! I calculated the disk’s velocity to be in the 500km/h range as it left the coil. Attempts to replicate this outdoors resulted in the disk being warped so severely that it completely lost its aerodynamic and spun out of control, stopping after climbing a good 100 meters.

Smaller version:

This one is powered by a smaller capacitor bank made up of two pulse rated electrolytic capacitors storing 12600uF at 450V (that’s 1.3kJ at full charge). They are switched through a SCR that is rated at 300A 1200V, and pulsed into a 7-turn flat solenoid that propels the same 3mm  thick 13cm

thick 13cm  outer dia, 4cm inner dia 70gram disk as on the experiment aboven. The coil used is wound with 16mm^2 welding cable (multi stranded copper). Click here or on the picture of the coil to watch a short (132KB) video of the entire setup firing a disk at just under 200Joules. You can hear 3 impacts: The first when the disk rises and the coil hits the table and bounces up. The second when the disk hits the roof (I chose this low partial charge so it wouldn’t rip chunks from the plaster ceiling:), and the third when it returns to ground. It is interesting to note that here the power switching is entirely solid state; a real achievement for the power levels the device operates at.

outer dia, 4cm inner dia 70gram disk as on the experiment aboven. The coil used is wound with 16mm^2 welding cable (multi stranded copper). Click here or on the picture of the coil to watch a short (132KB) video of the entire setup firing a disk at just under 200Joules. You can hear 3 impacts: The first when the disk rises and the coil hits the table and bounces up. The second when the disk hits the roof (I chose this low partial charge so it wouldn’t rip chunks from the plaster ceiling:), and the third when it returns to ground. It is interesting to note that here the power switching is entirely solid state; a real achievement for the power levels the device operates at.

The Real Thompson's Coil:

It consists in a large coil of wire wound around an iron coilform made up of several smaller metal rods. The rods are insulated from one another and prevent eddy currents from dissipating too much power inside the coil. The coil has enough inductance that when 220V 60Hz AC flow through it, they only draw 5A or so of current. The alternating magnetic field set up around the core repels any conductive rings placed in it, and heats them in the process. By clicking on the picture you can see a video of a liquid nitrogen cooled copper ring floating around the core in a presentation on electromagnetic repulsion and heating by induction that I gave for my IB HL-2 Physics class. I will post technical details on the coil here shortly.

For more experiments dealing wi th electromagnetism and electromagnetic induction and repulsion, electromagnetic mass acceleration, high power switching and more, be sure to check:

th electromagnetism and electromagnetic induction and repulsion, electromagnetic mass acceleration, high power switching and more, be sure to check:

What's next?

Check out my new beauties!

To the left you see a pair of MAXWELL pulse discharge capacitors, rated at 7.5kV, 36uF (1kJ) each. The series inductance (ESL) is 100nH, and they are rated for a repetitive discharge current (Apk) of 25Kiloamperes (60kA non repetitive). Each capacitor measures 30 X 11.5 X 9.5cm (1′ by 4.6″ x 3.8″) and weights 4kilos (talk about energy density!). The discharge terminals are 1cm diameter bolts.

To the left you see a pair of MAXWELL pulse discharge capacitors, rated at 7.5kV, 36uF (1kJ) each. The series inductance (ESL) is 100nH, and they are rated for a repetitive discharge current (Apk) of 25Kiloamperes (60kA non repetitive). Each capacitor measures 30 X 11.5 X 9.5cm (1′ by 4.6″ x 3.8″) and weights 4kilos (talk about energy density!). The discharge terminals are 1cm diameter bolts.

To the right you see 7 AEROVOX Energy Discharge Capacitors, each rated at 5200V, 23uF (311J), and with a series inductance of 150nH. Peak current is 5000A repetitive (12.5kA non-repetitive) Each measures 25 X 11.5 X 7cm, and weights 2.4 kilos. The discharge terminals here are also 1cm diameter bolts. The energy in each one of the smaller caps amounts to slightly over the maximum a cardiac defibrillator can deliver (their inductance is a lot lower though). I believe they were originally used to pulse a flash lamp in an airport.

This type of capacitors is also used to power flash lamps in pulsed lasers… Each of the larger caps costs around 2000 dollars new, whilst the smaller ones for about half that price. I obtained the Aerovox caps in a local surplus shop for $100, and the Maxwells through mail order, for $250. All Aerovox caps are currently assembled on a 162.2uF (measured), 5200V (2,2kJ) 21.4nH ESL bank that will be used in a Can Crusher, a high voltage Coil Gun, a Rail Gun, and some experiments with water atomization by pulsed discharge… The capacitor bank measures 50x25x11.5cm and weights 17.6kilos. They are interconnected through 1.5cm wide, 3mm thick copper buss bars. I am currently completing the pneumatically actuated high speed switch that will allow me to discharge them safely and noiselessly onto the above mentioned loads.

This type of capacitors is also used to power flash lamps in pulsed lasers… Each of the larger caps costs around 2000 dollars new, whilst the smaller ones for about half that price. I obtained the Aerovox caps in a local surplus shop for $100, and the Maxwells through mail order, for $250. All Aerovox caps are currently assembled on a 162.2uF (measured), 5200V (2,2kJ) 21.4nH ESL bank that will be used in a Can Crusher, a high voltage Coil Gun, a Rail Gun, and some experiments with water atomization by pulsed discharge… The capacitor bank measures 50x25x11.5cm and weights 17.6kilos. They are interconnected through 1.5cm wide, 3mm thick copper buss bars. I am currently completing the pneumatically actuated high speed switch that will allow me to discharge them safely and noiselessly onto the above mentioned loads.

Please Donate to PowerLabs so I can continue to fund more experiments!

© 2022 Copyright by Sam Barros. All rights reserved.

Removing any material from this site for display without consent from its author consists in an infringement of international copyright laws and can result in fines up to $50000 plus legal costs per infringement.